Robotic Palletizer Manufacturers Suppliers: The Future of Manufacturing

The use of robotic palletizers in the manufacturing industry has revolutionized the way products are handled and packaged, providing a number of benefits to businesses across a wide range of industries. By automating the process of palletizing and packaging products, these machines save time and energy while increasing efficiency and productivity.

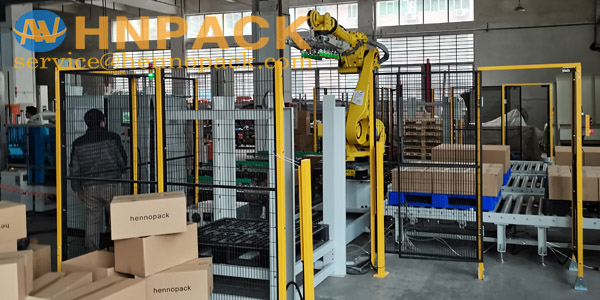

Robotic Palletizers

Robotic palletizers are machines that use robotic arms to stack and move products onto pallets. These machines can handle a wide range of products, from small parts to large, heavy items, and can be programmed to perform a variety of tasks, such as packing, wrapping, and labeling. Plus, they can be customized to meet the specific needs of different businesses.

Benefits of Robotic Palletizers

The use of robotic palletizers provides a number of benefits for businesses in the manufacturing industry, including:

1. Increased Efficiency and Productivity

Robotic palletizers are faster and more efficient than human workers, which means they can handle more products in less time. This helps businesses to increase their output, reduce production costs and potentially expand their customer base. Plus, since robotic palletizers don’t require breaks or time off due to sickness, they can work around the clock without interruption.

2. Improved Product Quality and Safety

Robotic palletizers are precise and accurate, which means they can stack products more evenly and in a uniform manner. This reduces the risk of products being damaged during transportation or storage, while ensuring that they look their best when they arrive at their destination. Plus, robotic palletizers can handle heavy and bulky items, which reduces the risk of injury for workers.

3. Cost Savings

The use of robotic palletizers can help businesses to save money by reducing labor costs, avoiding costly mistakes and minimizing product waste. Plus, since these machines are designed to be energy efficient, they can also help businesses to save on electricity costs.

4. Scalability

Robotic palletizers can be easily scaled up or down depending on the volume of products that need to be produced. This makes them ideal for businesses that need to quickly adjust their production levels to meet changing demand.

5. Easy Maintenance

Robotic palletizers require minimal maintenance and are designed to be durable and reliable. With regular maintenance and servicing, these machines can operate for years without needing significant repairs or replacement parts.

Conclusion

Robotic palletizers are quickly becoming the future of manufacturing, providing a number of benefits to businesses across a wide range of industries. By automating the process of palletizing and packaging products, these machines save time and energy while increasing efficiency and productivity. Plus, they provide improved product quality and safety, cost savings, scalability, easy maintenance and more.

Yantai Allok Automatic Equipment Co., Ltd. is one of the leading manufacturers of robotic palletizers in China. The company specializes in making the finest quality pallet solutions, including hydraulic and pneumatic cylinders, hydraulic EPC engineering solutions, and high-end cylinders. With its focus on quality and innovation, Yantai Allok is sure to play a major role in the growing market for robotic palletizers.