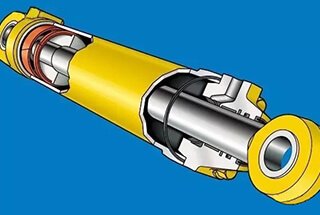

Types of Hydraulic Cylinders

Hydraulic cylinders come in different types, each designed for a particular application. Here are the most common types of hydraulic cylinders you should consider:

1. Double-acting cylinder: This type of cylinder has two ports to allow the hydraulic fluid to act on either side of the piston, resulting in bidirectional force.

2. Single-acting cylinder: A single-acting cylinder has one port, allowing hydraulic fluid to flow in one direction and return by an external force such as a spring.

3. Telescopic cylinder: These are multi-stage hydraulic cylinders that feature two or more pistons nested within each other. They are suitable for applications that require an extended stroke.

4. Tie-rod cylinder: Tie-rod cylinders have a piston that travels the length of a tubular body, which is fitted with steel tie-rods to withstand high pressures.

5. Welded cylinder: Welded cylinders are a single-piece construction, making them ideal for high-pressure applications.

Key Cylinder Specifications and Considerations

When selecting hydraulic cylinders, you need to consider various factors to ensure they meet your application needs. Here are the key specifications and considerations you should keep in mind.

1. Stroke length: This is the distance that the cylinder extends and retracts. Make sure the stroke length is long enough to achieve your desired motion.

2. Cylinder bore diameter: The diameter of the bore determines the amount of force the cylinder can exert. A larger bore diameter will provide a higher force.

3. Operating pressure: The operating pressure is the amount of pressure the cylinder needs to produce the desired force. Check the pressure rating of the cylinder to ensure it can handle your operating pressure requirements.

4. Mounting type: The mounting type determines the ease of installation and compatibility with your equipment. Common mounting types include flange, clevis, and trunnion mounts.

5. Material construction: The cylinder's material construction determines its durability and strength. Common materials include steel, aluminum, and composite materials.

Short Stroke Hydraulic Cylinders

Short stroke hydraulic cylinders are hydraulic cylinders that have a shorter stroke length than standard hydraulic cylinders. They are ideal for applications that require a limited travel distance and precise control. Short stroke hydraulic cylinders have several benefits, including:

1. Improved accuracy: Short stroke hydraulic cylinders offer precise control, resulting in better accuracy and less error.

2. Faster operation: Due to the reduced stroke length, short stroke hydraulic cylinders offer faster speeds, ideal for applications that require quick response times.

3. Lower installation costs: Short stroke hydraulic cylinders require less space, making them more compact and easier to install. This translates to lower installation costs.

Applications of Short Stroke Hydraulic Cylinders

Short stroke hydraulic cylinders have a wide range of applications in various industries, including:

1. Packaging industry: Short stroke hydraulic cylinders are ideal for providing precise control for filling, sealing, and labeling machines in the packaging industry.

2. Robotics: Short stroke hydraulic cylinders are critical components in the robotics industry, where they provide precise control for movement and positioning.

3. Automotive industry: Short stroke hydraulic cylinders are used in automotive assembly lines, where they provide precise control for various tasks like welding, riveting, and bolting.

4. Medical equipment: Short stroke hydraulic cylinders are used in medical equipment like MRI machines, where they provide precise motion control for improved accuracy.

Conclusion

When selecting hydraulic cylinders for your application, consider the type, features, and applications where they will be used. Short stroke hydraulic cylinders offer precise control, faster operations, and lower installation costs, making them ideal for applications that require limited travel distance and precise control. Finally, always ensure the hydraulic cylinder's specifications meet your operating pressure, mounting, and material requirements to avoid safety risks and enhance performance.